History

John T. Parsons (1913-2007) of Parsons Corporation in Traverse City, MI is considered the pioneer of the numerical control, the precursor to the modern CNC machine. For his work, John Parsons has been called the father of the 2nd industrial revolution. He needed to manufacture complex helicopter blades and quickly realized that the future of manufacturing was connecting machines to computers. Today CNC-manufactured parts can be found in almost every industry. Because of CNC machines, we have less expensive goods, stronger national defense and a higher standard of living than is possible in a non-industrialized world. In this article, we’ll explore the origins of the CNC machine, different types of CNC machines, CNC machine programs and common practices by CNC machine shops.

In 1946, the word “computer” meant a punch card operated calculation machine. Even though Parsons Corporation had only made one propeller before, John Parsons convinced Sikorsky Helicopter that they could produce extremely precise templates for propeller assembly and manufacturing. He ended up inventing a punch-card computer method to calculate points on a helicopter rotor blade. Then he had operators turn the wheels to those points on a Cincinnati milling machine. He held a contest for the name of this new process and gave $50 to the person who coined “Numerical Control” or NC.

In 1958, he filed a patent to connect the computer to the machine. By the early 1970s, however, the US army itself popularized the use of NC computers by building and leasing them to numerous manufacturers. The CNC controller evolved in parallel with the computer, driving more and more productivity and automation into manufacturing processes, especially machining.

What is CNC Machining?

CNC machines are making parts around the world for almost every industry. They create things out of plastics, metals, aluminum, wood and many other hard materials. The word “CNC” stands for Computer Numerical Control, but today everyone calls it CNC. So, how do you define a CNC machine? All automated motion control machines have three primary components – a command function, a drive/motion system, and feedback system. CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape

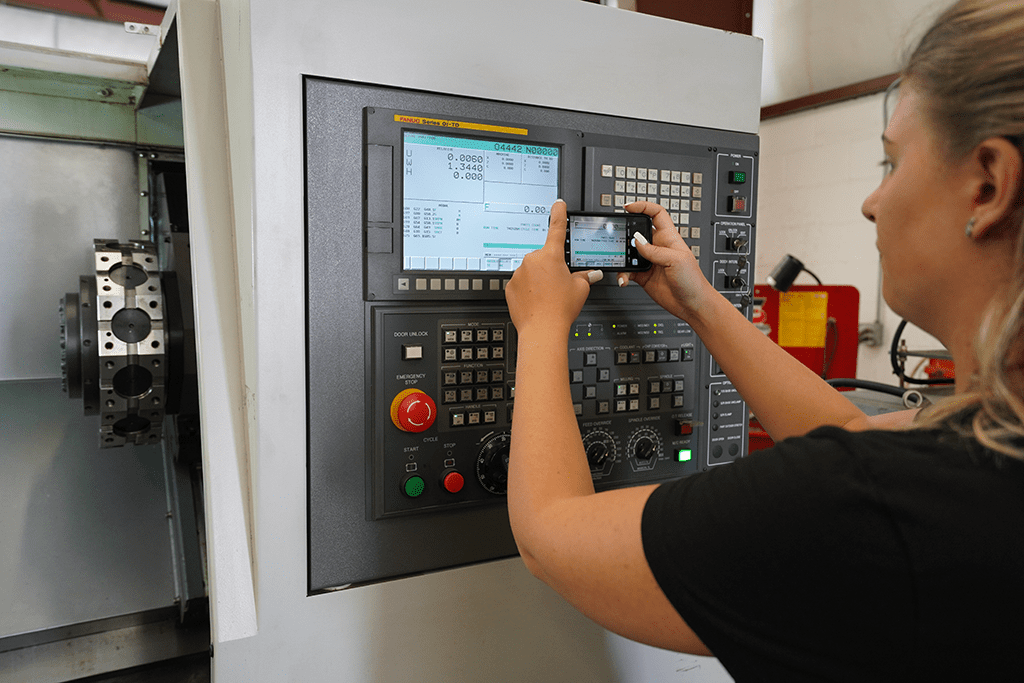

The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software. The software writes G-code that the controller on the CNC machine can read. The computer program on the controller interprets the design and moves cutting tools and/or the workpiece on multiple axes to cut the desired shape from the workpiece. The automated cutting process is much faster and more accurate than a manual movement of tools and workpieces which is done with levers and gears on older equipment. Modern-day CNC machines hold multiple tools and make many types of cuts. The number of planes of movement (axes) and the number and types of tools that the machine can access automatically during the machining process determine how complex a workpiece a CNC can make.

Computer Aided Drawing (CAD)

CAD software is the starting point for most CNC projects. There are many different CAD software packages, but all are used to create designs.

Computer Aided Manufacturing (CAM)

CNC machines often use programs created by CAM software. CAM allows users to set up a “job tree” to organize workflow, set tool paths and run cutting simulations before the machine does any real cutting. Often CAM programs work as add-ons to CAD software and generate g-code that tells the CNC tools and workpiece moving parts where to go. Wizards in CAM software make it easier than ever to program a CNC machine.

Types

Below are basic types of CNC machines:

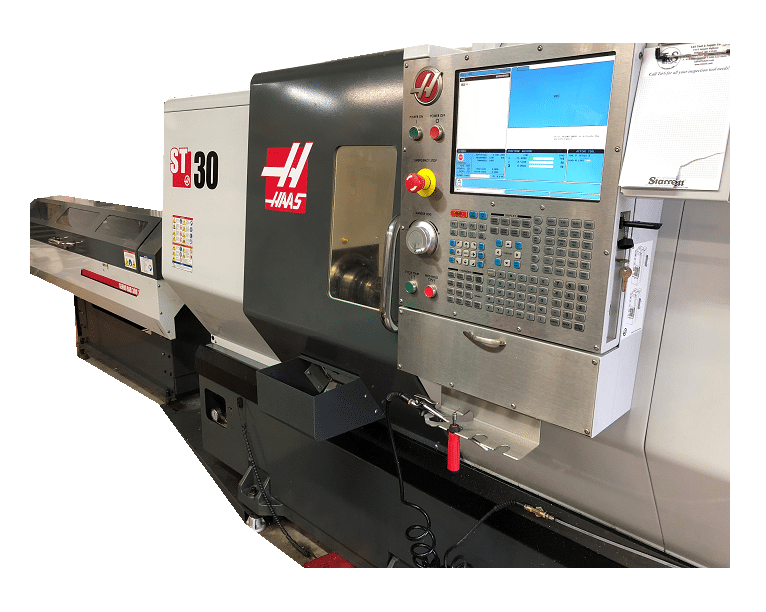

Lathes: This type of CNC turns the workpiece and moves the cutting tool to the workpiece. A basic lathe is 2-axis, but many more axes can be added to increase the complexity of cut possible. The material rotates on a spindle and is pressed against a grinding or carving tool that makes the desired shape. Lathes are used to make symmetrical objects like spheres, cones, or cylinders. Many CNC machines are multi-function and combine all types of cutting.

Routers: CNC routers are usually used to cut large dimensions in wood, metal, sheets, and plastics. Standard routers operate on 3-axis coordinate, so they can cut in three dimensions. However, you can also buy 4,5 and 6-axis machines for prototype models and complex shapes.

Milling: Manual milling machines use handwheels and lead screws to articulate a cutting tool onto a workpiece. In a CNC mill, the CNC moves high accuracy ball screws to the exact coordinates programmed instead. Milling CNC machines come in a wide array of sizes and types and can run on multiple axes.

Plasma Cutters: The CNC plasma cutter uses a powerful laser to cut. Most plasma cutters cut programmed shapes out of sheet or plate.

3D Printer: A 3D printer uses the program to tell it where to lay down small bits of material to build the desired shape. 3D parts are built layer by layer with a laser to solidify the liquid or power as the layers grow.

Pick and Place Machine: A CNC “pick and place” machine works similar to a CNC router, but instead of cutting material, the machine has many small nozzles which pick up components using a vacuum, move them to the desired location and put them down. These are used to make tables, computer motherboards and other electrical assemblies (among other things.)

CNC Machines can do many things. Today computer technology can be put on just about machine imaginable. The CNC replaces the human interface needed to move machine parts to get the desired result. Today’s CNC’s are capable of starting with raw material, like a block of steel, and making a very complex part with precise tolerances and amazing repeatability.